Design

Using state of the art Technologies is a part of our quality policy. The use of CATIA during the part design makes is possible to attain max. productivity and creativity, from the product definition to the product in the application.

KANCA is also able to receive data in Pro/E format from the customers. Any product of KANCA appears first on the computer screens. Solid models of the products are transfered to the FEM analaysis softwares enabling the visualisation and optimization of the forming processes.

Forging processes simulation and CAD/CAM development tools, are coupled to obtain better production and design cycles. Design parameters and tuned by optimizing the die loads and material flow so possible production problems are determine beforehand. Integrating simulation, modeling and CNC production into the design process ensures the safe, high-quality production.

Die Shop

The next most important issue in producing the perfect part lines is a set of dies produced correctly andaccurately according to the design. Every stage of dies is designed in our CAD/CAM facilities using CATIA and the process is simulatedbefore committing to metal.

Then, dies are manufactured using themost up-to-date CNC high speed machinery in our die shops. Dies are fully tested before being released toproduction.

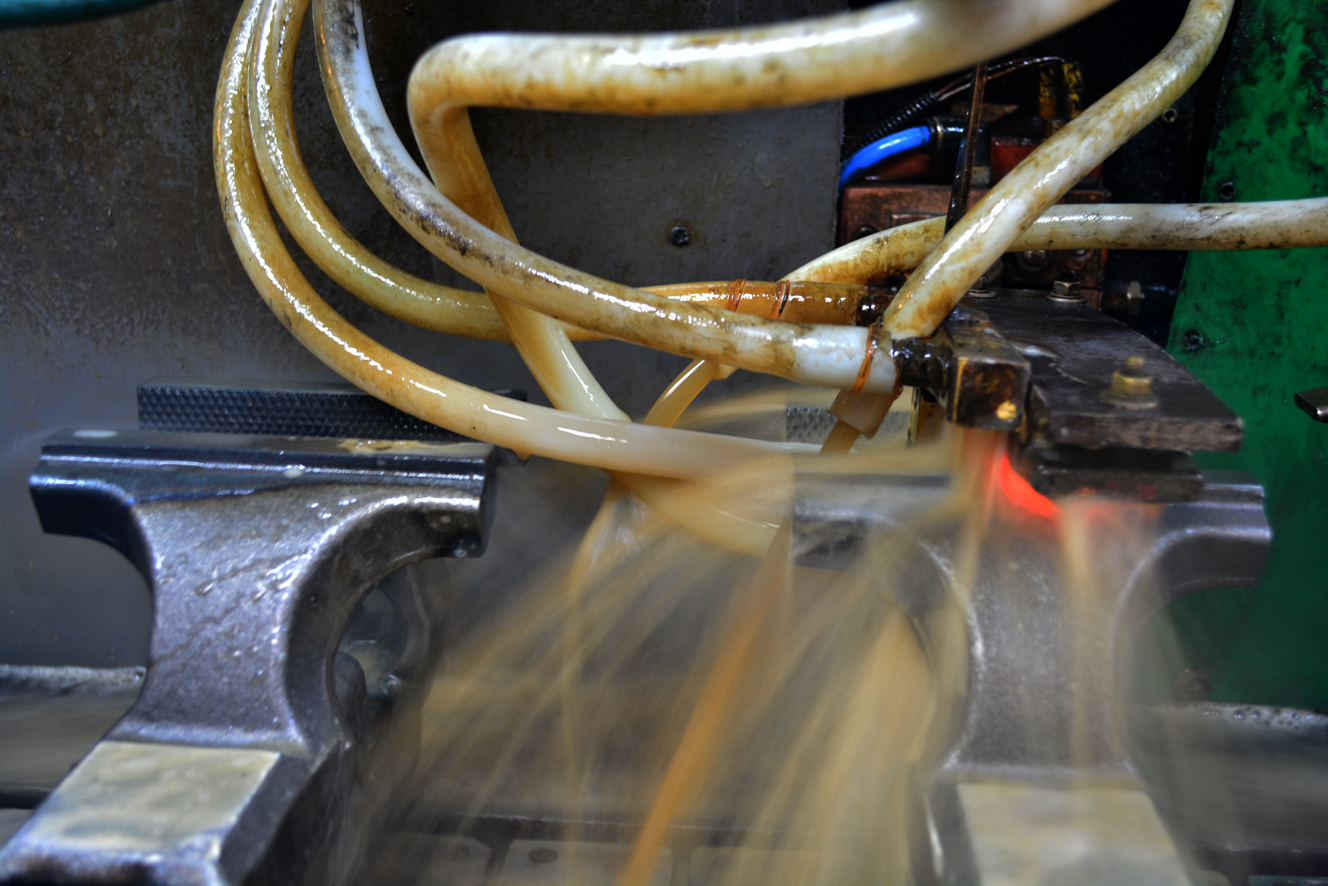

Forging

Pre-cut steel are heated in compeuterized induction furnaces for accuate temperature control and documentation according to customers’ requirements. Forging presses and hammers can produce parts of all levels of complexity from 0.5 kg to 20 kg /1.10-44.06 pounds) and up to 300 mm (12.59 inches) diameteror 750 mm lenght.

With proper pocess and die design along with flexible production capabilities we have been able to produce small lot size down to a couple of thousands per batch economically. The fact that more than %30 of production is composed of safety parts used in automobiles show clearly the confidence of our costomers in us.

Heat Treatment

In our most up-to-date heat treatment facilities, we can perform all the necessary operations, such as normalization, tempering, hardening, isothermal annealing, controlled cooling, blackening etc. Under fully compurterized and atmosphere controlled conditions. Depending on the customer date, all the process data can be supplied.

Furthermore, we can offer induction hardening up to 9 mm (0.30 iches) depth on small as well as very large parts in our vertical and horizontal induction machines.

Machining

We have 3-axes and 4-axes CNC machining centers, C-axes CNC turning centers, twin-chuck CNC turning centersas well as more conventional machining facilities to produce the most demanding parts. Indeed, we have specialized in producing safety parts such as front axles, and yet we can offer economical solutions to simpler or smaller lot-size parts, too. Using the modern technology, we have been able to attain scrap levels of less than %0.03.

Quality Assurance

We have been certified to conform to ISO 9001 and ISO 16949: IATF by BVQI and a re certified manufacturer according to AD-WO/TRD required for high pressure boilers. All our production and quality assurance procedures are geared towards customer satisfaction. Finally our ISO 14001 certification underlines our environmental commitment. For Railway industry Kanca has HPQ certificate and awarded from DB as Q1 class supplier. Recently Kanca received ISO 27001 and AEO certificates.

Stock and Logistics

Pre-cut steel are heated in compeuterized induction furnaces for accuate temperature control and documentation according to customers’ requirements. Forging presses and hammers can produce parts of all levels of complexity from 0.5 kg to 20 kg /1.10-44.06 pounds) and up to 300 mm (12.59 inches) diameteror 750 mm lenght.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.